CNC Step-lap Transformer Core Cutting Machine

Brief description

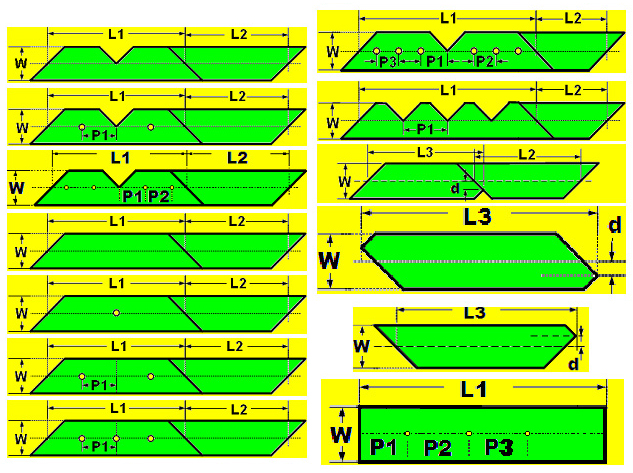

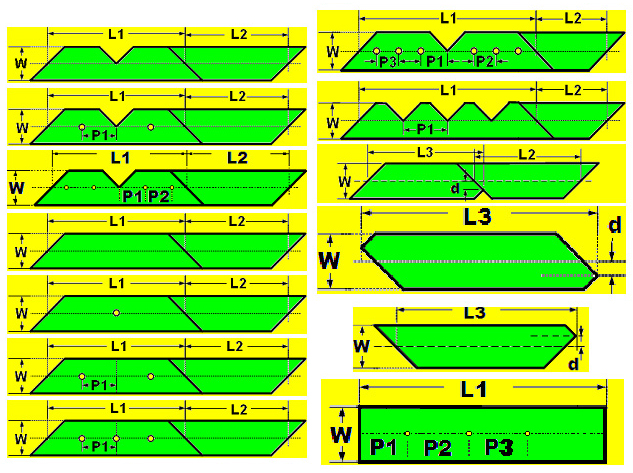

Our JN serious machines are designed with swing shear cutting system, online O punching and V notching system, capable of cutting all kind of laminations in transformer core production:

Angles, hole position, V notching position, cutting length, step lap parameters can be pre-set on HMI, full automatic, simple operation.

Main features

* Delta servo system plus Delta PLC, high precision, quick response

* Capable of cutting all transformer laminations including center limb

* Both horizontal & vertical step-lap cutting, max. 7 steps, each step can be two laminations

* Quick HMI setting, simple and convenient

* Carbide cutting blade, notching blade and punching die, long life, less burr

* Good cutting speed in cheap price:

Main technical data

Main technical data

|

No. |

Item |

Data |

|

1 |

Type Code |

JN-2003/3003/4003/5003/8003 |

|

2 |

CRGO thickness |

0.23-0.6mm |

|

3 |

CRGO coil width |

30-200/300/400/500/800mm |

|

4 |

Cutting length |

1-999999mm |

|

5 |

Cut-to-length tolerance |

+/-0.1mm |

|

6 |

Cutting angle tolerance |

+/-0.03° |

|

7 |

Hole position tolerance |

+/-0.1mm |

|

8 |

Notch position tolerance |

+/-0.1mm |

|

9 |

Burr height |

Less than 0.02mm |

|

10 |

Feeding speed |

Max. 100m/min |

|

11 |

Production speed |

30~60 pieces per minute |

|

12 |

Punching/notching die |

Carbide alloy |

|

13 |

Cutting blade |

Carbide alloy |

|

14 |

Die & blade life |

More than 1.2 million times before grinding |

|

15 |

Max. step-lap stroke |

40mm |

|

16 |

Step-lap quantities |

1, 2, 3, 4, 5, 6, 7 |

|

17 |

Servo motors |

Delta from Taiwan |

Previous:No

Next:Full Servo Step-lap Transformer Core Cut-to-length Line

CNC swing shear step-lap transformer lamination cut to length line is our patent transformer core cutting machine:

CNC swing shear step-lap transformer lamination cut to length line is our patent transformer core cutting machine: